Faculty of Mechanical Engineering

Data Resource

Unsteady airfoil at transitional Reynolds numbers with flow control

A Resource for CFD validation and Model Development

In collaboration with

Introduction

Recent interest in air vehicle gust-response, wind-energy and high-speed rotorcraft, among other applications, has focused attention on surging (streamwise oscillation of) airfoils. Airfoils may be subject to simultaneous surge and pitch, where the flow can be attached, partially separated, or massively separated. Under these unsteady conditions, there is often a desire to control these flows with the objective, for example, of minimizing unsteady loads or maximizing net aerodynamic efficiency.

This website serves as a resource, containing, inter alia, surge and pitch data acquired on a NACA 0018 airfoil in the Reynolds number range 65,000 to 750,000. Data includes active flow control, introduced by means of a blowing slot, near the airfoil leading-edge. All data were acquired in a specially designed unsteady wind tunnel. The data sets consist of surface pressure measurements, integrated aerodynamic coefficients, and selected two-dimensional particle image velocimetry (PIV). The intention is to provide data sets for validation of CFD codes, development of low-order models, and to provide comparisons with other unsteady facilities. Examples of these are given on this website.

A list of all test cases including a detailed description of the data acquisition procedure can be downloaded here.

Experimental Setup

The Unsteady Wind Tunnel

The Technion’s Unsteady Low-Speed Wind Tunnel (UWT) is a blowdown facility powered by 75kW double-entry (laterally-symmetric), backward-bladed centrifugal “airfoil-type” blower. The impeller lateral symmetry minimizes side-to-side vibrations and backward-blading produces a smooth pressure rise in the blade-stall regime. The blower is coupled to a large angle (20.6° half-angle divergence) diffuser and a coarse mesh was installed at the midpoint of the diffuser. A flexible rubber blower-diffuser coupling isolates blower vibrations. The diffuser connects to an anti-swirl section and a segmented plenum, where a course mesh is mounted between the first and second plenum segments. An 8:1 composite contraction nozzle, constructed from four identical sides, produces a 1000x610mm exit nozzle that discharges into the 1004x610x2000mm test sections. A louver system, adopted to force unsteady oscillation, is mounted on the furthest downstream test section module. Finally, the air discharges into a radial diffuser. Under steady conditions, with the louvers removed, the maximum wind speed is 55m/s and flow distortion and overall turbulence level, in the upstream test section module, are less than 0.2% and 0.1% respectively. The louver mechanism comprised N=13 counter-rotating vanes, each vane has a chord length of lv=70mm, thickness of tv=4mm and spans the entire width (w) of the test section module exit (see Figure 1). A 750 watt computer-controlled servo-motor with a 5:1 gear ratio was attached to the central vane, thus enabling the dynamic control of the vanes’ position, and the programming of arbitrary rotation profiles.

Technion Computational Fluid Dynamics Laboratory

(a)

(b)

The Pitching Mechanism

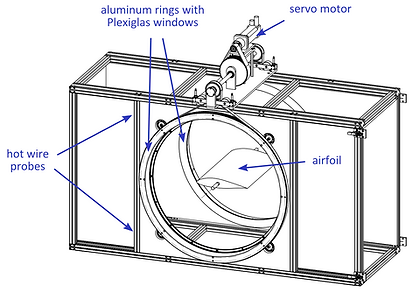

The test section is equipped with large rings, each mounted on four bearings, and transparent Plexiglas windows (Figure 2). The rings are driven by a servo-motor via a series of two belt drives. The floor and ceiling are also constructed from Plexiglas, rendering full optical access to the test section. The rings can perform arbitrary pitching motion of the airfoil through a full 360° at a maximum rate of 150°/s. This custom built test section with arbitrarily large angle-of-attack range, combined with high pitching speeds and full optical access renders this setup unique. This system, in conjection with the louver system, was programmed using LabVIEW with the so-called CompactRIO (or cRIO) real-time controller (National Instruments).

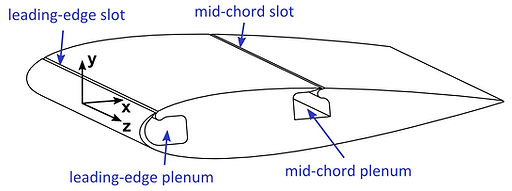

Data were acquired on a NACA 0018 airfoil by mounting it between the Plexiglas windows with the axis of rotation located at 25% chord. A schematic of the airfoil is shown in Figure 3. The airfoil was equipped with 40 mid-span surface pressure ports (ID0.8mm) symmetrically distributed along the upper and lower surfaces. Six additional pressure ports were located at chordwise positions of x/c = 21.5% and x/c = 69.5% on the suction surface as well as x/c = 69.5% on the pressure surface at a distance of 100mm from each side wall (z/s ≈ 0.16 and 0.84 respectively). The airfoil was mounted inverted in the test section (slots below) to facilitate PIV measurements.

Figure 1. Photographs of the louver system attached to downstream test section for the present experiments with the radial diffuser removed: (a) vanes fully open; and (b) vanes fully closed.

Figure 3. Schematic of the NACA 0018 airfoil showing leading-edge and mid-span blowing slots.

Figure 2. Schematic of the test section of Technion wind tunnel, showing the servo-motor and belt drives as well as the airfoil location.

Slot Blowing Systems

The momentum of the jet ejected from the control slot was adjusted with an Alicat Scientific “MCR 3500” mass flow controller. In addition to the high degree of accuracy (0.8% of reading + 0.2% of full scale), this allowed for dynamic variations of the momentum coefficient at time scales in the order of 0.1s. For the tests involving unsteady and adaptive blowing, the momentum time profiles were synchronized with the pitching motion and the wind speed oscillations using LabVIEW. The pressurized air from the mass flow controller entered the airfoil plenum from both sides. Measurements using hot wire probes confirmed that the spanwise deviations of slot velocity were negligible. A Ceccato “CDX 36” refrigeration dryer was installed upstream of the controller. The mass-flow controller and associated tubing are shown in Figure 4.

Figure 4. Photograph of the slot blowing system, showing the mass-flow controller and tubing system designed to provide air to both sides of the plenum.

References

-

Greenblatt, D., “Unsteady low-speed wind tunnels,” AIAA Journal, Vol. 54, No. 6, June 2016, pp. 1817-1830. https://doi.org/10.2514/1.J054590.

-

Mueller-Vahl, H., Strangfeld, C., Nayeri, C.N., Paschereit, C.O and Greenblatt, D., “Control of Thick Airfoil Deep Dynamic Stall Using Steady Blowing,” AIAA Journal, Vol. 53, No. 2, 2015, pp. 277-295. https://doi.org/10.2514/1.J053090.

-

Strangfeld, C., Müller-Vahl, H.F., Nayeri, C.N., Paschereit, C.O. and Greenblatt, D., “Airfoil in a High Amplitude Oscillating Stream,” Journal of Fluid Mechanics, Vol. 793, 2016, pp. 79-108. https://doi.org/10.1017/jfm.2016.126.

-

Müller-Vahl, H., Nayeri, C.N., Paschereit, C.O and Greenblatt, D., “Dynamic stall control via adaptive blowing,” Renewable Energy, Vol. 97, 2016, pp. 47-64. https://doi.org/10.1016/j.renene.2016.05.053.

-

Williams, D.R., Reißner F., Greenblatt, D., Müller-Vahl and Strangfeld, C., “Modeling lift hysteresis on pitching airfoils with a modified Goman-Khrabrov model,” AIAA Journal, Vol. 55, No. 2, 2017, pp. 403-409. https://arc.aiaa.org/doi/10.2514/1.J054937.

-

Müller-Vahl, H., Nayeri, C.N., Paschereit, C.O and Greenblatt, D., “Matched Pitch Rate Extensions to Dynamic Stall on Rotor Blades,” Renewable Energy, Vol. 105, 2017, pp. 505-519. http://dx.doi.org/10.1016/j.renene.2016.12.070

-

Medina, A., Ol, M.V., Greenblatt, D., Müller-Vahl, H. and Strangfeld, C., “High Amplitude Airfoil Surging: Complimentary Wind and Water Tunnel Experiments,” AIAA Journal, 2018. https://doi.org/10.2514/1.J056408.